Leather Glossary

Leather glossary

Glossary of

leather industry terms

Many, but not

all, of the

following terms

are taken from

the

International

Glossary of

Leather Terms

published by the

International

Council of

Tanners in 1968.

|

Aniline Dyed |

Leather that has been dyed

by immersion in a dyebath and has not received any

coating of pigment finish. |

|

Antique Grain |

A surface pattern of

markings or creases, usually irregular, in which the

hollows are often given a contrasting colour to produce

a two-tone or two-colour effect. The creases are

produced by embossing, boarding or other similar means. |

|

Back |

(1) The main portion of a

hide, obtained by cutting off the two bellies. (2) Leather made from this part. |

|

Bark Tanned |

Leather vegetable tanned

mainly by means of the tannins contained in the barks of

trees, especially oaks, the leather in process coming in contact with the

raw bark. (see also Chroming, Tawing). |

| Bating | The

process of steeping hides and skins in an alkaline bath,

to separate the lime, oil and glutinous matter, and

render them soft and pliable, and fit for tanning.

Originally the alkaline bath was a mixture of hen and

pigeon droppings, it was later carried out using dog

dung - called 'puering' (qv). This was often followed by

'scudding' (qv) being the removal of hair roots and

other unwanted material. Modern 'Bates' contains

manufactured enzymes and stabilising agents. |

|

Belly |

(1) Part of the hide

covering the underside and the upper part of the legs of

the animal. (2) Leather made from this part. |

|

Belly Grain |

The tanned outer (hair or

grain) layer split from a belly. |

|

Buffed Leather |

Leather from which the top

surface of the grain has been removed by an abrasive or

bladed cylinder or, less generally by hand. |

|

Buffing |

(1) The thin grain of

leather removed from a cattle hide by the splitting

machine. (2) The process of more or less removing the grain layer by abrasion. (3) Removal of the flesh side of the leather by mechanical abrasion to produce a suede effect, or to reduce the substance. Synonymous with "fluffing" and now in more common use. |

|

Butt |

The part of the hide after

the bellies and shoulders have been removed. |

|

Butt Split |

The under layers, split

from the butt of a cattle hide. |

|

Cattle Hide |

The outer covering of a

fully grown bovine animal. |

|

Chagrin / Shagreen |

A leather with a rough

surface. |

|

Chamois Leather |

(1) Leather made from the

flesh split of sheep or lambskin, or from sheep or

lambskin, from which the grain has been removed by

frizing, and tanned by processes involving the oxidation

of fish or marine animal oils in the skin, using either

solely such oils (full oil chamois) or firstly,

formaldehyde and then such oils (combination chamois). (2) Leather made from the skin of a mountain antelope or chamois (such leather is rare). |

|

Chrome Retan |

Leather which has been

first chrome tanned throughout its thickness and

subsequently further treated or tanned with vegetable

and/or synthetic tanning agents and/or resin filling

materials, these agents penetrating notably, but not

necessarily completely, into the interior. |

|

Chroming |

The

tanning process whereby the pickled pelt is converted to

leather using chromium salts. (See also bark tanning,

tawing). |

|

Clout Leather |

Leather for shoe mending. |

|

Combination Tanned |

Leather tanned by two or

more tanning agents, e.g. chrome followed by vegetable

(chrome re-tan), vegetable followed by chrome

(semi-chrome), formaldehyde followed by oil (combination

oil). |

| Cordwainer | Shoemaker. Originally, a

leather worker using high quality Cordovan leather from

Spain for such things as harness, gloves and riding

boots. By the nineteenth century it had reduced to a

shoemaker - as distinct from a cobbler, who repaired

shoes. |

|

Corrected Grain |

Leather from which the

grain layer has been partially removed by buffing to a

depth governed by the condition of the raw material and

upon which a new surface has been built by various

finishes. |

|

Cow Hide |

(1) The outer covering of a

mature female bovine animal. (2) Leather made from unsplit cow hide or its grain split. |

|

Crust |

The

skins are dried in special stoves after dressing,

leaving them 'in the crust' - a harsh, stiff, unworkable

state. |

|

Curried Leather |

Leather, usually vegetable

tanned, which has been subjected to the currying

process, i.e. a series of dressing and finishing

processes applied to leather after tanning in course of

which appropriate amounts of oils and greases are

incorporated in the leather to give it increased tensile

strength, flexibility and water-resisting properties. |

| Currier / Curryer | A person who dresses and

colours leather after it is tanned. |

| Degreasing |

The act or process of removing grease from a greasy

object; specifically, the removal of fatty matter from

raw sheep's wool often by the solvent action of

petroleum naphtha. |

|

Deliming |

Deliming follows the liming process (qv), and any

residual lime is removed by a thorough washing in rotary

paddle machines. |

|

Doling |

One of

three methods of skin preparation, used primarily for

thin kid and lamb skins, which were stretched on a slab

and a sharp chisel-like tool was used. This operation,

like 'paring' (qv) was replaced by wheeling and fluffing

in which the skins are reduced to an even thickness by

means of a revolving emery wheel. |

|

Drenching |

An

infusion of bran, meal and flour in which the skins were

placed and left to ferment. This, by reason of its acid

nature, swells the skins prior to tanning. |

| Dub | To rub grease into leather. |

|

Dyeing |

Dyeing

has always been a part of the leather dressing process

but today's dyes are more permanent. |

|

Embossed Leather |

Leather embossed or printed

with a raised pattern either imitating or resembling the

grain pattern of some animal, or quite unrelated to a

natural grain pattern. |

| Fell | Animal hide or skin with

hair; thick or matted hair or wool, fleece. |

| Fellmonger | Dealer or worker in hides, skins and

furs. Also recycled inedible animal parts for glue,

fertiliser, offal, horn, bone, gut etc. Basically, he

ran the "knacker's yard". |

|

Finish |

(1) The final process or

processes in the manufacture of dressed leather. (2) The surface coating applied to a leather. |

| Fisher | A tanner's implement. |

|

Fleshing |

The

removal of the flesh adhering to a skin or hide.

Originally carried out by hand with a special sharp

knife, the process today is carried out by machines with

fast-revolving blades. |

| Fleshmonger | (1) Tannery worker

(2) Butcher |

|

Flesh Split |

(1) The inner or

under layer of a hide or skin separated from it by the

splitting machine. (2) Leather made from (1). |

| Fluff | To buff leather. |

| Frizz | To rub leather to smooth

and soften. |

| Frot | To soften leather by

rubbing. |

| Forrel / Fozzel | A kind of parchment used

for covering books. |

|

Full |

(1) Leather made from the

unsplit, or full thickness, of hide or skin, e.g. full

sheep. (2) Leather tanned solely with one agent, e.g. full chrome in contrast to semi-chrome, and full oil in contrast to combination oil. |

|

Full Chrome |

Leather tanned solely with

one agent, e.g. full chrome in contrast to semi-chrome,

and full oil in contrast to combination oil. |

|

Full Grain |

Leather bearing the

original grain surface as exposed by removal of the

epidermis and with none of the surface removed by

buffing, snuffing or splitting. In contrast see

"corrected grain". |

|

Grain |

(1) The pattern

characterised by the pores and peculiar to the animal

concerned, visible on the outer surface of a hide or

skin after the hair or wool and epidermal tissue have

been removed. (2) An abbreviation for "grain split". |

| Grainer | A tool to impart a grain in

leather. |

|

Grain Layer |

The portion of a hide or

skin extending from the surface exposed by removal of

the hair or wool and epidermis down to about the level

of the hair or wool roots. |

|

Grain Leather |

Leather which has the grain

layer substantially intact and which is finished on the

grain side. |

|

Grain Split |

The outer (wool or hair)

layer of a hide or skin that has been split into two or

more layers. |

| Grindery | The tools and materials of

leather workers. |

|

Hide |

(1) The outer covering of a

mature or fully grown large mammal, e.g. cattle, horse,

camel, elephant and whale. (2) Leather made from (1) which has not been split, or from the grain split of such hide; when used in this way the name of the animal e.g. cowhide or oxhide or the type of leather, e.g. bag hide or case hide, may be added. |

| Hidebound | Edged with leather. |

| Hided | Made of twisted leather. |

|

Leather |

Hide or skin which still

retains its original fibrous structure more or less

intact, and which has been treated so as to be

imputrescible even after exposure to water. The hair or

wool may or may not have been removed. Certain skins,

similarly treated or dressed, and without the hair

removed, are termed "fur". NOTE: No product is described correctly as "leather" if its manufacture involves breaking down the original skin structure into fibres, powder or other fragments by chemical or mechanical methods and reconstituting these fragments into sheets or other forms. |

| Leathern | Made of leather. |

|

Liming |

Liming

is one of the main steps carried out during leather

production in the tannery. The main purpose of liming is

to separate the hair from the hides. Originally the

skins were placed in large pits containing slaked lime

and water and left for several weeks - probably the

origin of 'Pit Lane',

one of the early names of Middle Street. Today, the

process is carried out in a drum over twenty-four hours. |

| Mace | A mallet to beat leather. |

| Moellon | A wax for leather. |

|

Mineral Tanned |

Leather that has been

tanned with mineral salts such as aluminium, chromium or

zirconium salts. |

|

Morocco |

(1) Vegetable tanned goat

skin leather with characteristic grain pattern developed

naturally or by hand boarding or graining only. The

commonest and most characteristic grain is hard grain.

(2) By long usage, especially in the fancy goods trade, goatskin of any vegetable tannage that has been hand boarded in the damp condition, but in the strict sense it should be limited to goatskin tanned exclusively with sumac. |

| Mulled | Treated to make softer. |

|

Nappa |

Soft full grain gloving or

clothing leather made from unsplit sheep or lambskin or

kid-skin. It is usually tanned with alum and chromium

salts and dyed throughout its substance. |

|

Nubuck |

Cattle hide leather buffed

on the grain side to give a velvety surface, white or

coloured. |

|

Oak Bark Tanned |

A light-weighing,

unbleached, bark tanned leather, which has been pit

tanned, at ambient temperature for not less than five to

six months by a process embodying layering for not less

than three months, oak bark being employed as a basis of

tannage. |

|

Paring |

Paring

is the final process before the leather is ready for

use. The skin is secured along one edge and then

scraping the rough side with a special paring knife

until the skin becomes stretched and soft. |

|

Parchment |

Translucent or opaque

material with a smooth surface, suitable for writing,

bookbinding and other purposes. It is made from the

flesh split of sheep, ass or goatskin, by drying out the

limed material without applying any tannage, the

material being thoroughly cleansed and degreased and

smoothed during the process. Generally the flesh split

of a sheepskin. |

|

Patent Leather |

Leather, one surface of

which is covered with an integral, flexible, waterproof

film which has a lustrous mirror-like surface. This

coating was formerly built up by the application of

various daubs, varnishes and lacquers, pigmented or

non-pigmented, based on linseed oil. |

|

Pebbling |

Using a roller to make an

indented surface on leather. |

|

Pickling |

After

bating (qv), the skins are brought to an acidic

condition by soaking in brine in a rotating drum for a

couple of hours. This is in preparation for chrome

tanning or for storage. |

|

Pigment Finished |

Leather to whose surface a

finish containing fine pigment particles in suspension

has been applied. |

|

Pricker |

A tool to put spaced holes,

as for sewing. |

|

Protected Leather |

Leather in which certain

special chemicals have been incorporated to render it

less liable to deterioration through exposure to

polluted atmospheres. The treatment is often applied to

vegetable tanned upholstery and bookbinding leathers. |

|

Puerring |

Pronounced 'purring', the origin is from the French

puer, to stink. The process of steeping hides and

skins in an alkaline bath, primarily of dog faeces, to

separate the lime, oil and glutinous matter, and render

them soft and pliable, and fit for tanning. (See also

'bating'). Following puerring, the skins are 'drenched'

(qv). |

|

Raw Hide |

(1) A hide which has only

been treated to preserve it prior to tanning. (2) Translucent material made from the whole substance (for industrial applications, principally in the textile industry) or the grain split (for luggage) of bovine hide freed from the hair and epidermal and flesh layers and dried out in the limed state, usually without any tanning process being applied. |

|

Rough Tanned |

Leather which after tanning

has not been further processed but has been merely dried

out. The term "rough tanned" is used chiefly in

connection with vegetable tanned hide leathers. e.g.

"rough tanned strap". |

|

Shamoy |

To work grease into

leather. |

|

Shrunk(en) Grain |

Leather specially tanned so

as to shrink the grain layer and having a grain surface

of uneven folds and valleys. Sometimes called "drawn

grain". |

|

Skin |

(1) General. The outer

covering of an animal. (2) In the strict sense. The outer covering of small mammals and other vertebrates, e.g. sheep and goats; or of the immature animals of the larger species, e.g. calves and colts. Used in relation to pigs, reptiles, birds and fish. (3) Leather, made from (1) and (2) which has not been split. (4) The outer covering of a fur-bearing animal dressed and finished with the hair on. |

|

Skiver |

(1)The tanned outer or

grain split of a sheep or lambskin. Sometimes applied to

goatskin. (2) The worker who splits leather. |

|

Skiving |

Thinning the leather at the

edges to avoid a double layer at a seam. |

|

Sleeker |

A tool to smooth leather. |

|

Smoothing |

An iron used to smooth

leather. |

|

Snuff |

To curry or smooth leather. |

|

Stamper |

A tool to beat leather

with. |

|

Split |

(1) A single layer from a

hide or skin that has been separated over its whole area

into two or more layers. The layers thus obtained are

termed: (a) grain split (outer split); (b) flesh split

(inner split); (c) in heavy hides there can also be a

middle split. (2) Leather made from the flesh split or middle split. |

|

Split Hide |

(1) The outer (hair or

grain) layer of a hide from which the under or flesh

side has been split to give it a reasonably uniform

thickness. (2) Leather made from (1). |

|

Stark |

A tool to dress leather. |

|

Stitch Wheel |

A tool to put spaced holes

(pricker). |

|

Suede |

(1) Velvet-like nap finish

produced on leather by abrasive action. (2) Leather whose wearing surface has been finished to have a velvet-like nap. |

|

Suede Split |

Leather made from the flesh

split of hide or skin and finished with a velvet-like

nap normally on the split surface. |

| Tawer | A

dresser of white leather without the use of tannin,

especially by soaking it in a solution of alum and salt. |

|

Tanning |

Processing whereby

putrescible raw hides and skins are converted into

leather. |

|

Tooling |

Using a variety of methods

/ tools to impress designs into a piece of leather for

decoration . |

|

Vegetable Tanned |

Leather tanned exclusively

with vegetable tanning agents, or with such materials

together with small amount of other agents used merely

to assist the tanning process or to improve or modify

the leather, and not in sufficient amounts to alter

notably the essential vegetable tanned character of the

leather. |

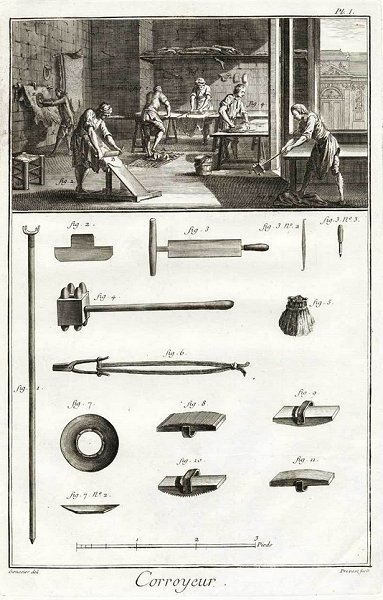

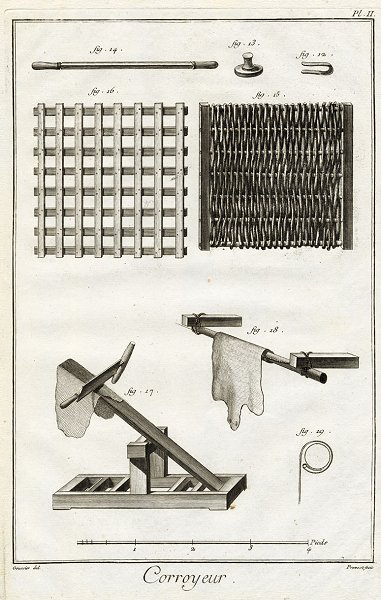

Two plates on leather dressing, from a book of 1751, showing some tools of the trade.