yeovil trades & traders

The petters story

From ironmongery to fire grates, engines, cars and airplanes

-

Petters

the Ironmongers

-

Petter &

Edgar -

Engineers and

Iron Founders

-

The

Nautilus Stove

Company

-

The Yeovil

Motor Car Co

Ltd

-

J B Petter &

Sons

-

Company

Rationalisation

and

Reorganisation

-

Petters Ltd

-

The

Beginning of

Westland

John Petter was born in 1821 and came from Barnstaple, Devon. As Percy Petter wrote in his autobiography "My father's father, John Petter had been in business in Barnstaple as an Ironmonger, and largely through the shrewd business instincts and thrift of his Cornish wife, Eliza - formerly Bazeley - from Hayle, he built up a comfortable little fortune and lived for many years of my young life at Ilfracombe, and later at the Grange, Yeovil."

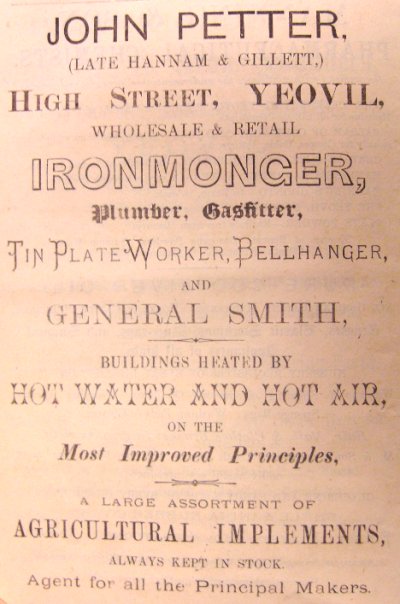

John Petter moved his family to Yeovil around 1865 when he purchased the ironmongery business of Hannam & Gillett in the Borough. His new ironmongery business was advertised in the Post Office Directory of 1866.

In 1870 John gave the ironmongery business to his son, James Bazeley Petter, as a wedding present on the latter's marriage. Nevertheless, John was advertising the business as "John Petter, Ironmonger", for years to come as seen in the 1878 advertisement below from Whitby's Yeovil Almanack Advertiser.

From this point on the fascinating Petter story gets ever more complicated as James Petter, and eventually his family, expanded and diversified their interconnected business interests. James, according to his son Percy, would always prefer to work in his ironmongery premises in the Borough while delegating the running of the various other enterprises yet maintaining a rigid overall control.

John Petter's advertisement in the 1878 edition of Whitby's Yeovil Almanack Advertiser.

From my

collection

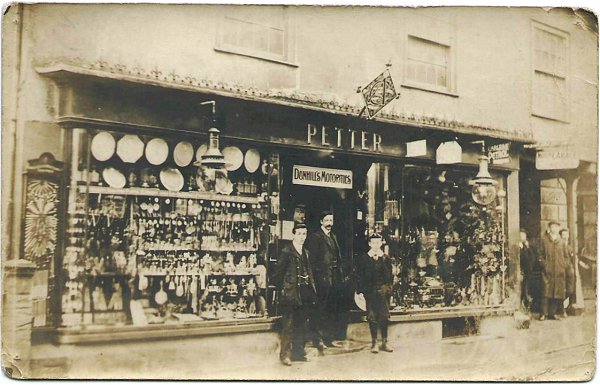

A view of High Street from the Borough probably taken in the 1890's with James Petter's shop at left. William Edwards had been in business in the building at least as early as early as 1790 when he was listed as an ironmonger and cutler in the Universal British Directory. In 1827 Josiah Hannam took over the premises, later the partnership of Hannam & Gillett. The business was bought by John Petter in 1865.

This colourised photograph

features in my

book 'Yeovil From Old Photographs'.

This photograph was taken by Yeovil Photographer Jarratt Beckett and published in his 1897 book "Somerset viewed through a Camera".

A postcard dated 1905 of Petter's second shop in High Street. The people at right are standing at the entrance to George Court and at extreme right is the first of the arches of the Town Hall.

This colourised photograph of High Street dates to about 1914, by which time the Town Hall clock tower had been built. The building at the far end is Stuckey's Bank that predated the present bank building and Petter's ironmongery at left. By this time the ironmongery business was being run by James' son, Hugh. The second shop is just seen between the tree and the Town Hall with a cart parked outside.

Petter & Edgar - Engineers and Iron Founders

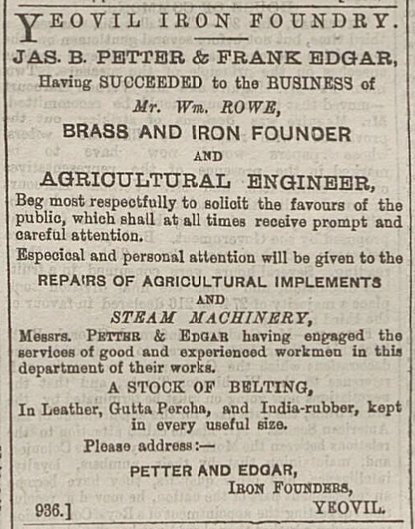

By 1872 James Petter, still only aged 25, had acquired the Yeovil Foundry and Engineering Works, primarily making and repairing agricultural machinery, and took the manager, Henry Frank Edgar (known as Frank), as a partner in the business. James Petter concentrated his efforts, as he would always do, on his ironmongery store in the Borough while Henry Edgar managed the foundry side of the partnership.

Western Gazette

- 7 June 1872

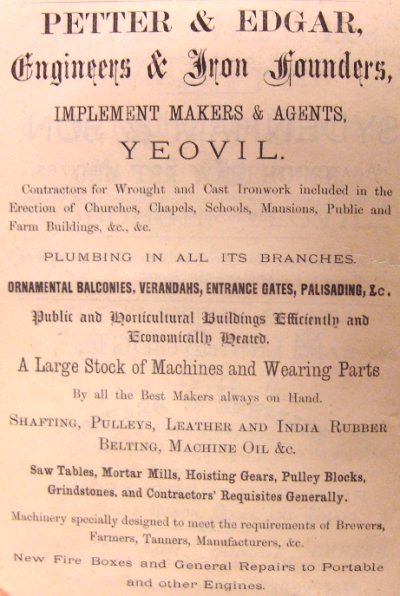

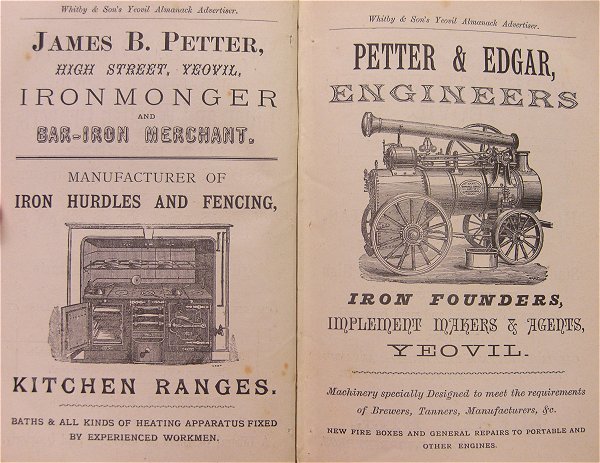

They advertised their new business in the Somerset & Bristol Directory of 1872 and the advertisement from Whitby's Yeovil Almanack Advertiser of 1878, shown below, testifies to the large range of products and services they offered.

The foundry would be the mainstay of the Petter enterprise from this point onwards.

Courtesy of

Richard Torrens

This cast iron oven front is in a cottage in South Perrott. It dates to the 1870s or 1880s since Petter & Edgar were partners at the foundry from 1872 until the death of Frank Edgar in January 1889.

James B Petter & Henry Edgar's advertisement in the 1878 edition of Whitby's Yeovil Almanack Advertiser extolling their large and diverse range of products and services.

Courtesy of John

Penny

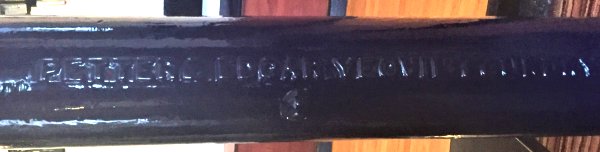

A cast iron column from the Petter & Edgar Yeovil Foundry, photographed in the skittle alley of the Rose & Crown at Bradford Abbas.

Courtesy of John

Penny

Although it's not too clear, with the wonders of computer technology, this is the same image turned to see the lettering - which says "Petter & Edgar Yeovil Foundry".

This

photograph

appears in my

book 'Secret

Yeovil'.

A two-page spread from Whitby's Yeovil Almanack Advertiser of 1883 showing at left an advertisement for Petter's domestic ironmongery business in the Borough and at right his iron foundry and Engineering business in partnership with Henry Edgar.

Courtesy of

Kelly and Phil

Waters

During modernisation of a cottage in Kingsdon, this bread oven was uncovered. Phil's cottage is called "The Old Bakery".

Courtesy of

Kelly and Phil

Waters

A close-up of the Kingsdon cottage bread oven. Bearing the name "James B Petter Yeovil" indicates it was manufactured after the 1889 death of Henry Edgar.

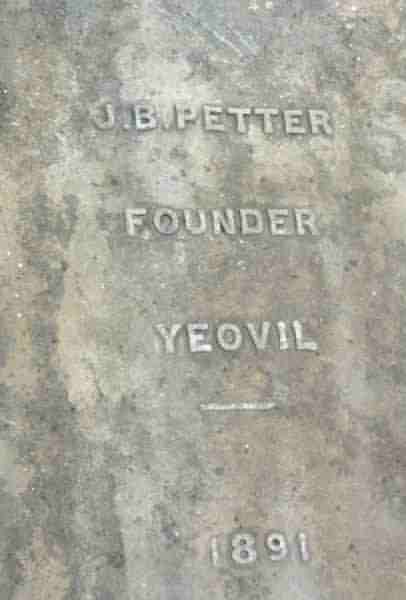

Very few people have seen this - the manufacturer's panel of St John's church's tower's lead roll roof, naming JB Petter, ironfounder. Photographed in 2021.

Courtesy of John

Penny

Employees of Yeovil Foundry, taken around 1901. On the extreme right, in bowler hat, is Hugh M Petter and next to him (also in a bowler) is Harry Hill (of Hill, Sawtell). Amongst others who have been identified in the picture are Walter Goff (foundry foreman), fourth from left. Others are - unknown; Meech, a moulder; unknown, Larcombe, a castings fettler; Sidney Drayton, agricultural machinist; unknown, Goff, moulder; unknown, Patten, a moulder; Edward Sutton, agricultural machinist; Tom Hares, millwright and machinist; Joe Fowler, in charge of foundry crucible; William Sutton, at one time a champion boxer of the Royal Navy.

Courtesy of Paul

Rimmer

Workers at the former Petter & Edgar foundry pose for a photograph in the 1920s. Second from left is 'Lossie' Pilkington and fifth from left is Alf Allen.

This

photograph

appears in my

book 'Secret

Yeovil'.

As far as I'm aware, this cast iron bollard in Waterloo Lane is the last survivor in Yeovil from Petter & Edgar's Iron & Brass Foundry. Photographed in 2013.

Around 1881 James designed a modern and efficient fire grate which he called the 'Nautilus' because its internal structure resembled the internal structure of a Nautilus shell in which smoke from the fire circulated before being expelled by means of a flue. Several versions of this efficient system, including a gas-fired model, were designed and manufactured.

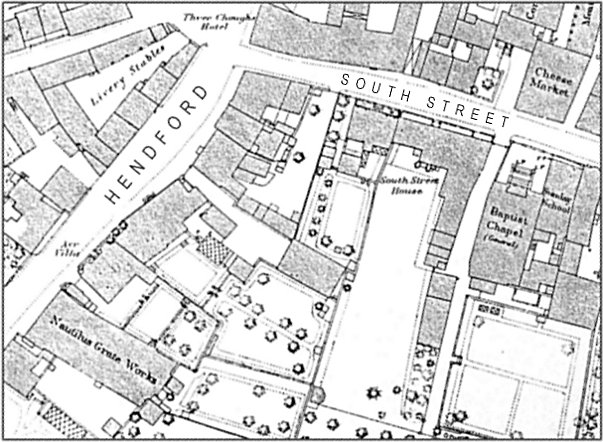

He founded the Nautilus Stove Company which made his fire grates and kitchen ranges at his Nautilus Grate Works in Hendford, next door to Ayr House and opposite the Manor Hotel (see map below). The site is now occupied by Dolphin House. Production later moved to the Nautilus Stove Factory in dilapidated buildings in Vicarage Street. However these premises proved to be too small to accommodate the ever-increasing production demands and consequently grate production ultimately transferred to the foundry in Clarence Street.

Three styles of grate were produced in the Yeovil foundry and sold in the ironmonger's shop in the Borough. The Boudoir grate, shown in the centre, was very similar to the original Nautilus form (the name being taken from the sea creature) and had external decoration representing various kinds of seaweed, shells, etc. The familiar Nautilus crest was used on the rear of the engine base or the early stationary engines.

In 1882 Petter's Nautilus grate was exhibited at the Manchester Smoke Abatement Exhibition but after Queen Victoria had one of Petter's grates installed at Osborne House and another at Balmoral his grates became nationally famous and demand for them grew substantially.

Courtesy of

Phill Sandford

A Nautilus grate insitu.

Courtesy of

Phill Sandford

The Serial Number plate on the back of the above grate.

In 1886 James' partner, Henry Edgar, died in a trap accident and management of the foundry was placed with Robert Corrie. In 1890 James' twin sons, Percy and Ernest, left school to start their apprenticeship in their father's ironmongery and foundry business. Percy initially worked in the foundry under Robert Corrie, later transferring to the Nautilus Stove Factory in Vicarage Street, working under his cousin Stephen Petter, while Ernest's talents were more inclined towards the clerical and accounting side of the business. Percy recalled in his memoirs "I was placed under Mr Corrie to learn my trade. There were some thirty to forty men employed making iron castings and making, but chiefly repairing, agricultural machinery."

In 1893 Robert Corrie resigned as manager of the foundry and James appointed his 20-year old son Percy as the new foundry manager. As Percy later recalled "I was really much too inexperienced for the position, and was to a large extent left to do the best I could on my own account. Fortunately we soon afterwards had an application for a position as Foreman from a Mr Jacobs of Martock, a member of the Engineering family of Sibley and an Engineer of the old brigade to his finger tips. He could make the drawings, make the patterns, do all the machine work and fitting, so of course he was able to instruct others in the same arts."

The Petter twins, Ernest and Percy, had always been interested in transport and even at the age of twelve Percy, under the guidance of his eldest brother, had "made some hand-propelled velocipedes.... and later used to hire a wood wheeled 'penny farthing' boneshaker."

The

first Petter Car

was originally

intended to be

electric-powered,

but there were

such

difficulties

with the

batteries, that

electricity was

abandoned as a

power source.

The

first Petter Car

was originally

intended to be

electric-powered,

but there were

such

difficulties

with the

batteries, that

electricity was

abandoned as a

power source.

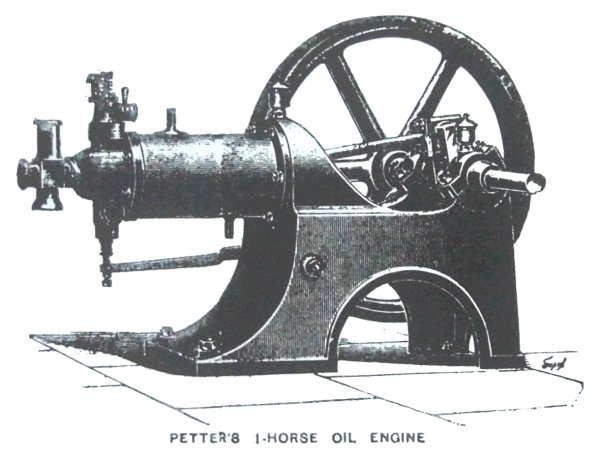

By 1892 Percy and Ernest had designed and produced a self-propelled oil engine and in 1895, together with their inventive Engineer, designer and foreman Ben Jacobs (photographed at left and who remained in service with the Petters until he was in his late seventies), they developed a new engine of one horse-power designed specifically to propel a 'horseless carriage'.

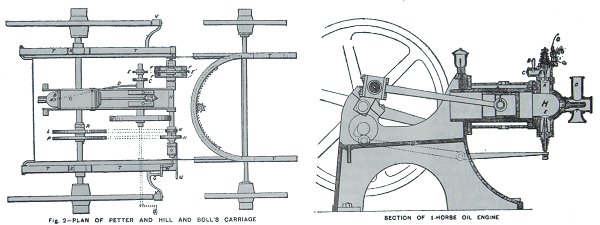

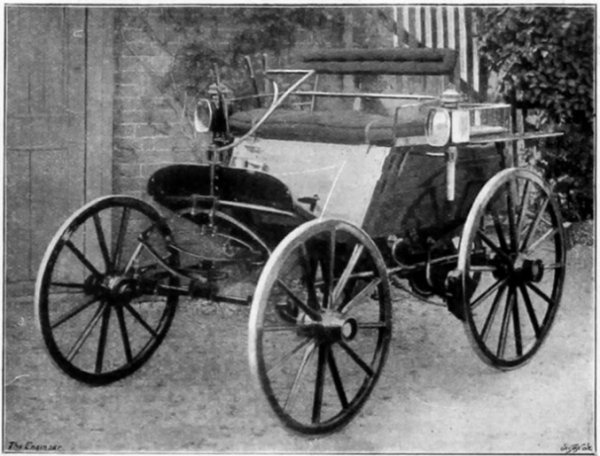

They produced the first motor car with an internal combustion engine to be made in the United Kingdom, using a converted four wheel horse-drawn Hill and Boll phaeton and a 3hp Petter horizontal oil engine. The vehicle was constructed at the Park Road carriage works of Hill and Boll. It weighed 9cwt (457kg), including the 120lb (54kg) of the Petter engine with its flywheel and side bars, and had a top speed of 12 miles per hour.

The original engine worked on compression ignition and required a blow-lamp heating a rod that passed through the cylinder head. Later they used a 'trip magneto'. The fuel tank was cylindrical and of cast iron on a short pipe leg secured to the top of the cylinder with gravity feed (drip-feed lubrication), to a cast iron float chamber - very crude, but cheap and effective.

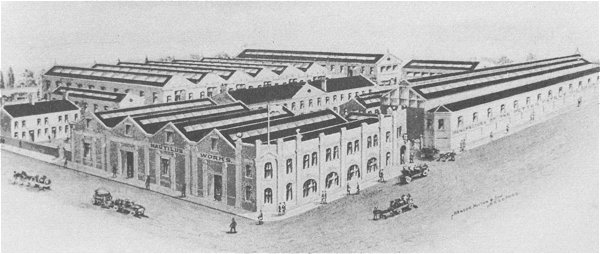

Believing they had a great opportunity the brothers, with their father, formed the Yeovil Motor Car Co Ltd in 1895 with a thousand pounds capital and a factory was built on the site of James' garden in Reckleford, later to be expanded as the Nautilus Works seen above.

The company was to make small two-person motor carriages, initially at their foundry in Huish / Clarence Street and then at Reckleford in conjunction with carriage makers Hill & Boll of Park Road. In all some twelve different 'horseless carriages' were developed. This same year the company was one of four that offered automobiles for trials at Chelsea with a first prize of a thousand guineas and their twelfth model, the 'Yeovil Car', was exhibited at the 1897 Motor Car Exhibition held at the Crystal Palace, both events being organised by 'The Engineer' magazine.

James Bazeley Petter (steering) sitting next to Herbert Southcombe, with twin sons Percy (left) and Ernest (right) in the rear seat, on one of their automobiles in a photograph of 1896 with coachwork by Hill & Boll. This photograph appeared in the 3 April 1896 edition of 'The Engineer' magazine, captioned "Petter and Hill and Boll's Oil-Motor Carriage" with an accompanying article and the plans illustrated below.

Percy Petter later wrote in his memoirs "In those days the law required that every mechanically propelled vehicle should be proceeded by a man walking with a red flag, and, as the horses were quite unaccustomed to 'Horseless Carriages,' they usually took fright when they saw one coming, and this gave us a lot of trouble. The police, however, kindly gave us permission to take the car out without the red flag before 8 o'clock am and many a run we had in the early mornings before the 'red flag' restriction was removed."

The following description of the Yeovil Car is from the same June 1897 edition of 'The Engineer' magazine "The Yeovil motor car is a light business carriage for two persons. It is driven by a two-cylinder Petter patent engine working on the Otto cycle, using ordinary petroleum. The cylinders are arranged side by side, and fired alternately. The explosions are effected by means of two ignition tubes, heated by a single blow lamp. The air inlet valves of the motor are operated by the suction of the piston, the exhaust valves by means of levers driven by chain gearing from the crank shaft. There is a choice of 2 gear ratios, providing fast and slow speeds of ten and four miles respectively. The rear axle drives one of the rear wheels of the carriage. A brake is held on the fly-wheel by a spring to control the engine when the carriage is at rest. When the carriage is in motion this brake is held off by a hand lever. Two pairs of ordinary carriage brakes were applied to the rear wheels, and the reversing mechanism provides a strong additional brake in case of emergency."

This

photograph

appears in my

book 'Secret

Yeovil'.

The 'Yeovil Car' with coachwork by Hill & Boll that was clearly a conversion of one of their normal horse-drawn coaches as illustrated in their advertisements. An illustration from 'The Engineer' magazine of 1897.

Another contemporary report stated "The carriage is intended for two persons, with which a speed of ten miles an hour is obtained on level road. It will mount the hills of the neighbourhood with two persons, but larger power would be used for four persons … The exhaust is, we are informed, quite invisible, and the engine almost noiseless. The removable handle was used to start the engine in the first place, and an arrangement is made so that the handle, when put in position, automatically opens the exhaust valve which closes instantly when, a good impulse being given, the handle is withdrawn and the engine starts … Tube ignition is adopted, and a small heating lamp is used … The engine starts in ten minutes and runs, we are told, without attention."

In March 1899 Petters announced in 'The Autocar' magazine that they were ceasing development and production of heavy oil carriages to concentrate on electric carriages - Percy had already built an electric motor when in his early teens! Unfortunately there was even less success with these electric vehicles.

An ill-fated electric carriage of 1898. It was powered by two electric motors, one driving each of the front wheels. Coachwork again by Hill & Boll.

However they failed to achieve the commercial success they had hoped for with automobiles, either with combustion engines or powered by electric. Indeed they almost bankrupted their company and consequently, and with some regret, abandoned automobile production and adapted their engines for agricultural and industrial use.

It was around this time that Ernest became discontented with his role within the business so left Yeovil in order to open what was, effectively, a sales office in Queen Victoria Street, London.

In the 1901 census James and Charlotte were still living above the shop in the Borough (although they would shortly move to a house in The Park) with their children - Guy, aged 28 and an engine maker; Percival, age 27 an iron founder; Hugh, age 26 an ironmonger; Mary, age 25; Gertrude age 24; Claude, age 20 a glove manufacturer; Evelyn, age 11 and Richard, age 9.

By this time the Petters were producing a range of stationary engines designed to run farm machinery such as chaff cutters, root pulpers and cream separators. Indeed they had been manufacturing cream separators under license at the stove works since the mid-1890's. Nevertheless the firm was in financial trouble and, according to Percy, one of the problems was that his father had brought five of his sons into the business but had given them little control. The sons began having management meetings among themselves but made little progress since their father refused to attend their meetings and frequently vetoed their decisions. It transpired that James was having a mild form of nervous breakdown but it was causing great concern for the business.

In 1901, as a financial crisis loomed, Ernest and Percy bought the business from their father following which they reorganised and renamed it as James B Petter & Sons (Ltd) with both the sons as joint managing directors. Also a director for over thirty years was John Vincent.

Their father James retired from business and moved briefly to live in Bristol although he shortly returned to Yeovil to live in his house 'The Grange' in The Park but died just five years later. His obituary in the 20 April 1906 edition of 'The Engineer' read "We regret to have to announce the death of Mr JB Petter, which took place at his house, West Park, Yeovil, after a very short illness, on Tuesday, April 17th. Mr Petter was the founder of the firm of James B Petter & Sons, and retired from active management in 1901. He was fifty-nine years of age, a member of several public bodies at Yeovil, and a magistrate for the borough."

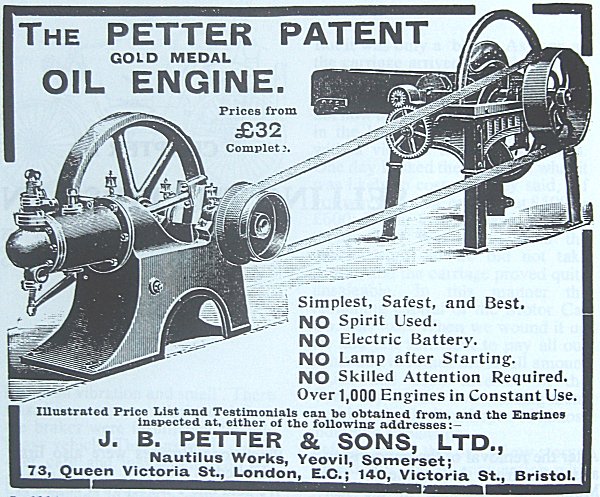

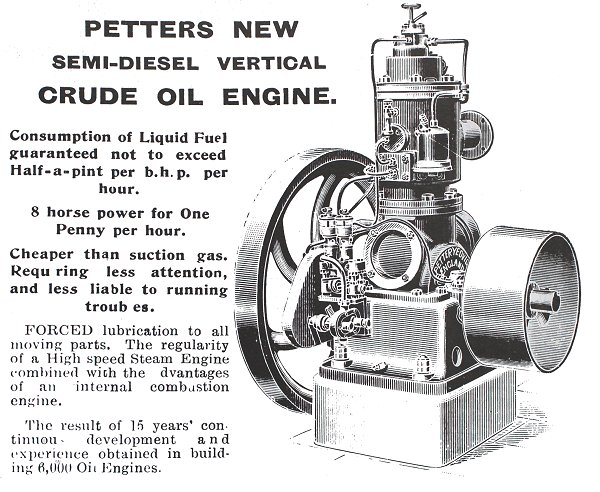

In the meantime business began to pick up, the company's financial problems were overcome and their oil engines became popular and sold well. By 1904, as seen in the advertisement below, over 1,000 had been sold.

The range of the Petter oil engine ran from 1hp to 30hp and over 1,000 had been sold by the time of this advertisement in 1904.

An illustrated postage cover from 1929 advertising Petter's oil engines.

Company Rationalisation and Reorganisation

While Percy and Ernest reorganised the company their brothers Harry and Hugh, trading under the name of 'HB & H Petter', managed the original business including the Foundry & Engineering Works in Clarence Street and particularly the ironmongery and hot water heating side of the company in the Borough.

But, as Percy recalled later "It was however for some reason not very prosperous, and Hugh left to commence business and carry on missionary work in Buenos Aires, and later Harry left with his family to take up farming in Australia."

That business was then formed into a Company under the name of Hill and Sawtell Ltd, in which the Petter family held the principal interest. HA "Jimmy" Hill and JW Sawtell had both been associated with the business for some years and Percy Petter remained a director of the company until the 1950's.

When the twins bought the company from their father it included the engine business and the stove business which was transferred to the new Nautilus Works in Reckleford. The stove side did not prosper even though a showroom was opened in the Tottenham Court Road, London. Eventually the stove section of the company was sold off to the Davis Gas Stove Co who were still manufacturing the Petter stoves into the 1930's.

The Clarence Street foundry was closed on the termination of the property's lease.

By about 1903 the whole of the Petter's enterprise was concentrated in the Nautilus Works at Reckleford and sales were becoming international and close trade links were established with Russia, Sweden and the Balkans. "The business continued to develop in a most satisfactory manner; almost every year the profits increased and we were constantly finding it necessary to add to the buildings and plant." recalled Percy.

In 1909 the company started making two-stroke engines, then called two-tack engines, which they found to be superior to their older four-stroke engines. In 1911 they were awarded the Grand Prix of the Milan International Exhibition giving the company a significant impetus.

In September 1911 the company sold its first V-type semi-diesel two-stroke engine, as seen in the advertisement above. Meanwhile the majority of their larger engines were produced for the export market. One of the larger engines, the 26 bhp portable P2T model illustrated below, was shipped in batches of several hundreds to Russia.

The P2T model, as with other larger portable engines, were designed to be self-contained units and came with all accessories and was mounted on strong girder frames with forged steel travelling wheels. The cooling water was pumped around the cylinder and cooled by a radiator assisted by a current of air.

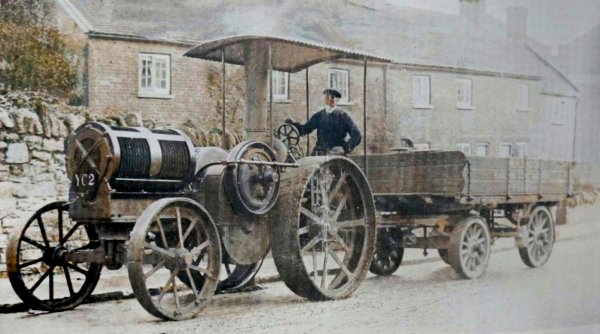

The Petter oil traction engine 'YC2' photographed in 1911 in Reckleford with the Nautilus Works on the corner of Goldcroft just visible at extreme right. This particular engine was owned by "WH Snook, Hauling Contractor, Yeovil" which is written on the side of the cart being pulled.

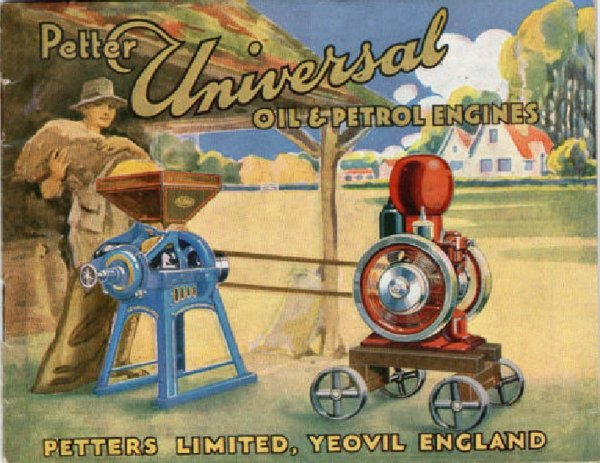

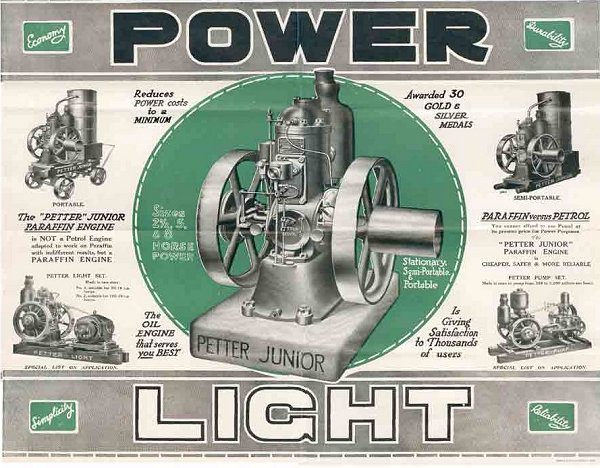

On a smaller scale, the 'Petter Junior' was a magneto ignition petrol / paraffin engine, designed specifically for the farming community. It appeared in 5hp form in 1913 with the first examples being sold through Hill, Sawtell & Co who had a ready-made agricultural outlet and were part owned by Petters. 1½ and 3hp models were subsequently added to the range and the name was changed to the Universal M-type engine.

Industrial checks were used to record that a workman was present on a shift, in relation to pay or as receipts for tools issued from a central store. Only two Yeovil companies are known to have produced industrial checks - Petters and Westlands.

|

|

|

These brass checks - the two in my collection are both stamped '246' on the plain reverse - were issued by Petters Limited. Around the edge of the obverse is "PETTERS LIMITED" and "YEOVIL" around a central nautilus, the logo of the company based on James Petter's Nautilus Fire Grate. These tokens probably date to the inter-war period and were used at the Nautilus Works in Reckleford. Of brass, the tokens are 32mm in diameter and 1.8mm thick. |

See also Yeovil Trade Tokens and Checks.

A 1928 advertisement for the Petter 'Universal' oil and petrol engines.

This advertisement for the Petter Junior engine dates to around 1930 and by 1934 over 50,000 engines of this series were in use all over the world with production continuing until 1940.

In 1912 the company went public and began engine production in the new factory named the Nautilus Works in Reckleford. Its workforce of some 500 men produced over 1500 engines a year.

A colourised photograph of around 1913 showing the blacksmith shop of Petters Ltd.

The First World War started in late 1914 and by early 1915 the Reckleford Works was already producing 18-pounder shell cases as seen in this photograph below. As the man went off to war, many women were employed in industries across the country. Petters was no different and employed women in their Reckleford factory from the first. The women seen in this photograph were employed to produce 18 pounder shells since in the first few weeks of the war nearly 400 male Petters employees went off to war.

In 1919 the company bought the Vickers factory in Ipswich and was renamed Vickers Petters Ltd. Unfortunately at this time their business interests were at adversely affected by labour disputes, both local and national, and the general depression of the 1920's, forcing Petters to buyout Vickers and ultimately transfer the business back to Yeovil. Here they erected a new Engineering building suitable for the construction of the larger engines they hoped to build at Ipswich.

In 1937 the engine industry was standardising its ranges and Petters Ltd. was acquired by a group of companies called the Associated British Oil Engine Co Ltd. Each individual company within the group carried on as an autonomous unit, but agreed to build a limited range of engines to avoid duplication and competition amongst themselves. Sir Ernest and Percy Petter became directors on the new board.

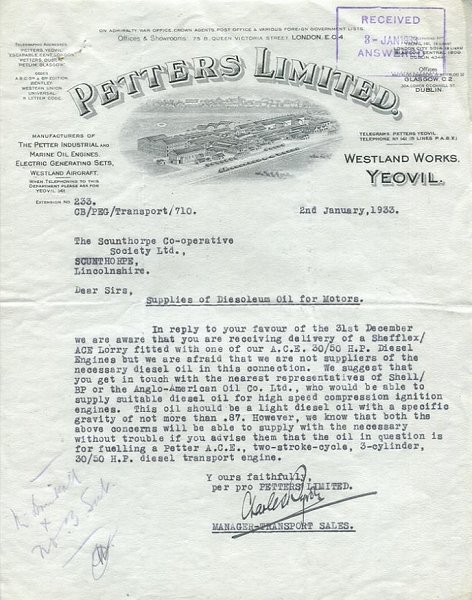

A letter dated 1933 on Petters Limited notepaper with an aerial view of the works.

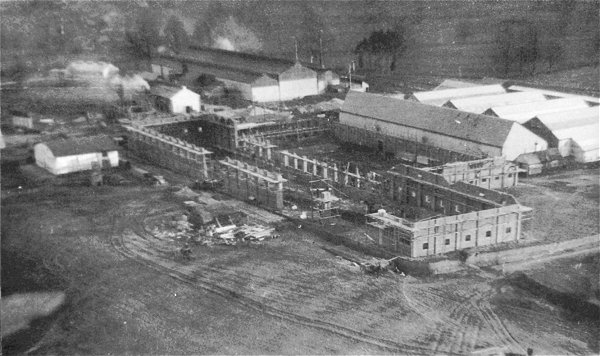

Percy explained the beginnings of Westland in his memoirs "By the beginning of 1913, the whole of the three acres of land at Reckleford which had originally been my father's garden, was occupied by buildings and necessary yard spaces; yet it was necessary at times to work night and day in order to supply the ever-increasing demand for Petter engines." He was persuaded by the manager of his foundry to inspect a field off West Hendford which sloped gently up from the Great Western Yeovil & Taunton branch railway. Enquiries were made into the ownership of the land and the possibility of getting sidings on the railway.

The land was purchased, together with some seventy five acres of farmland to the north of the works for a proposed 'garden village' of houses and amenities for the anticipated huge increase in Petter employees. Percy continued "Mother and I with Norah and Kathleen had gone down one Saturday afternoon in 1913 to cut the first sods for the foundations of the new Foundry and mother chose the name Westland, which has since become famous all over the world. The new Foundry, one of the largest in Great Britain, was ready for occupation early in 1914 and the first casting was poured."

See also - Thomas Frederick Hardyman

Courtesy of John

Green

The outside of the new foundry in a colourised photograph of 1913.

Courtesy of John

Green

The inside of the new foundry in a colourised photograph of 1913.

Courtesy of John

Green

The staff of the Westland Foundry - all 214 (I counted them) - pose for a group photo on 16 January 1919.

The Westland factory, with new buildings being erected in 1917.

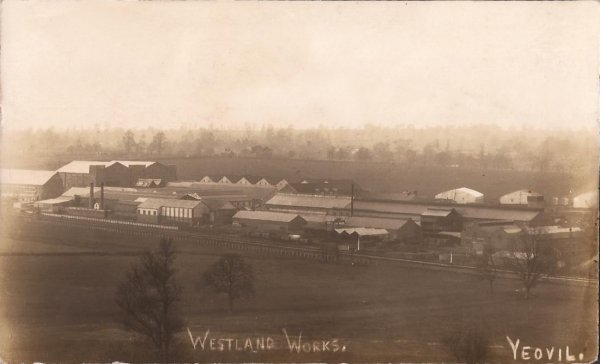

The Westland Works, produced as a postcard, probably late 1917 or early 1918. Note the three canvas hangars, for keeping aircraft in, at centre right.

Women factory workers at the Westland factory during the First World War.

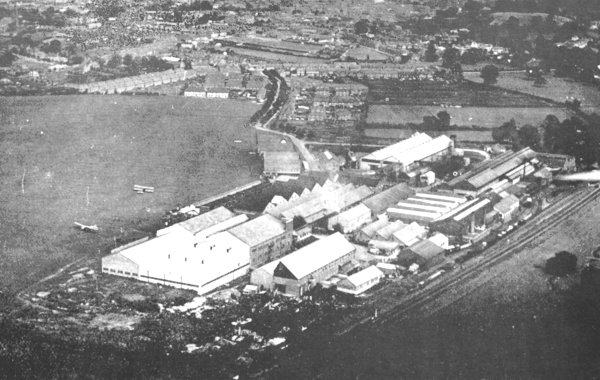

An early post-First World War aerial view of Westland Ltd. Note the proximity of the railway line running across the lower right of the photograph next to the works - this was one of the prime considerations in creating the works at this location. Note also the houses started to be built in Westland Road in what was originally intended to be a 'garden village'.

In early 1915 Ernest brought forward a resolution at one of the board meetings that the directors would be happy to place all the resources of the company at the disposal of the government, and were prepared to undertake the manufacture of any war materials for which the works might be considered suitable. A copy of this resolution was sent to the Board of Admiralty and to the War Office.

Within a couple of weeks a letter was received in reply saying that it was thought that Petters might undertake the construction of naval aircraft. The result was an order for twelve Short Type 184 patrol seaplanes (photographed above), followed by a contract to build twenty Short Type 166. The completed seaplanes were transported to Hamble for flight testing. The success with the seaplanes resulted in a contract to build Sopwith 10 Strutters.

By 1916 construction of the factory and airfield was well in hand. Completion of Sopwith contracts was quickly followed with an order to build de Havilland 4 and 9 twin seat bombers. These were often delivered directly to the Western front and it became a Westland custom to ballast the rear seat of these aircraft with a barrel of local cider.

Towards the end of the war, Westland were sub–contracted by de Havilland to install the American Liberty engine in the DH–9 to produce the DH–9A (photographed above). Having completed this work satisfactorily, Westland became the prime contractor for the type and this was an important factor in establishing Westland as a major company in Britain’s aircraft industry. Westland were also contracted to build 75 Vickers Vimys and had completed 25 of these when the war ended.

The total contribution of war material by Petters, as well as some thousands of engines, was nearly 1,000 aeroplanes of all kinds, and a vast number of 18 pounder shell cases and gun carriage equipment. The Westland Works were expanded beyond all recognition, huge buildings covering vast areas as required for aircraft were erected and equipped with all the necessary plant.

Courtesy of

Martin Longhurst

The large, well-equipped Petters Band formed by men from all different areas of Petters Ltd, photographed in the 1920s.

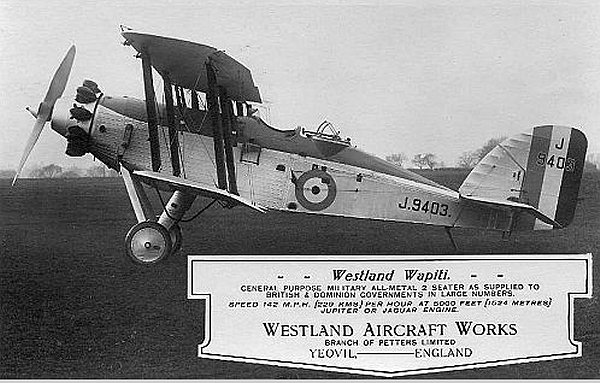

The de Havilland DH–9A continued in production until 1927 and was followed by the Wapiti (photographed above). This incorporated many DH–9A airframe components and was the winner of the competition for a General Purpose aircraft. It was to become the mainstay of RAF Middle East and Indian operations between the wars and a total of 563 were built. The continuous production of the Wapiti, and its successor the Wallace, were a mainstay for the company during the years of the depression.

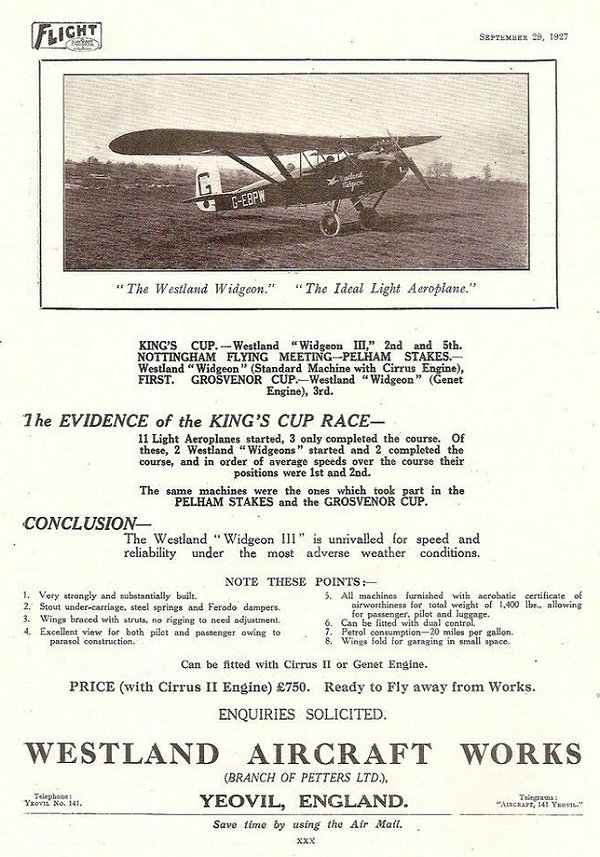

A full-page advertisement extolling the virtues of the Westland Widgeon in the 29 September 1927 edition of Flight magazine. Yours, ready to fly, for just £750 (a snip for about £120,000 at today's value).

From my

collection

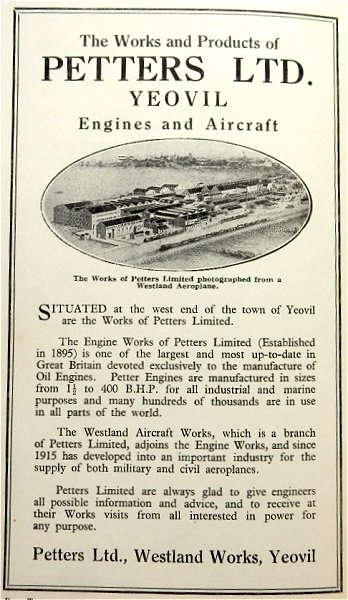

A Petters Ltd advertisement dating to 1931.

A general view of the foundry, photographed in 1934.

From my

collection

The masthead from the Petter's Monthly News in-house magazine. This issue from 1935.

A number of

unusual designs

were seen at

Westlands in the

inter-wear

period including

the

Westland–Hill

Pterodactyl

tailless

aircraft

(photographed

above) and the

sleek Wizard

monoplane

fighter. In 1933

a modified

Wapiti (The

Westland–Houston

PV–3) flew over

the summit of

Everest

(29,030ft).

The first Lysanders (advertisement above) were designed by Teddy Petter and flew at the end of 1936. They were already in service by the time war broke out in 1939 with several squadrons sent to France. They fared badly against the Luftwaffe however and were used throughout the war in the search-and-rescue role although, with their short take-off and landing capabilities, what remains in the national consciousness was the part they played in dropping agents behind enemy lines in France.

In 1937 the Petter twins, Ernest and Percy, both retired and in 1939 Associated British Oil Engine Co Ltd acquired the Petter engine business thus ending the family's long and fruitful association with Yeovil.

From my

collection

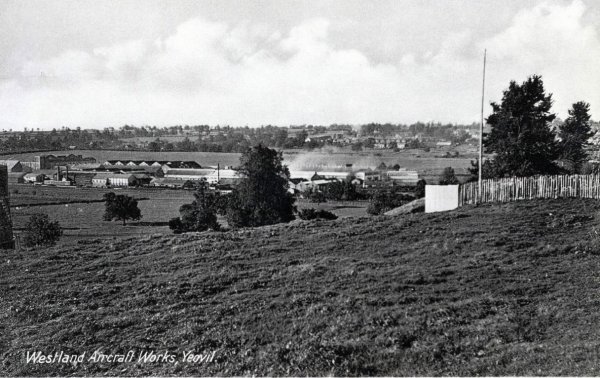

A postcard of the 1930s showing the 'Westland Aircraft Works'.

As the Second World War approached, British government aircraft production increased. In response, the new chairman of Associated British Oil Engine Co Ltd and of Petters Ltd, A.P. Good, moved all engine production to the British Electrical Engine Co plant in Loughborough. Westland Works became Westland Aircraft Co and went into full production for the government and ultimately, of course, Westland Aircraft went on to become a major manufacturer of helicopters.

|

|

|

These two aluminium industrial checks in my collection were issued by Westland Aircraft after the Second World War. Both are just under 33mm in diameter and 1.7mm thick. The reverse of both are plain. The example at left reads "WESTLAND AIRCRAFT" around the top and "JIGS AND TOOLS" around the bottom while that to the right is worn at centre but reads "SMALL TOOLS" across the bottom. |

See also

Yeovil Trade

Tokens and

Checks.

The Westland machine shop. Photographed in 1934.

The Westland core shop, Photographed in 1934.

Maps

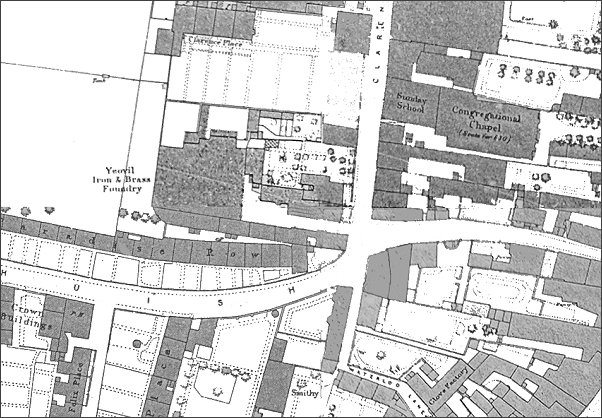

Map based on the 1886 Ordnance Survey showing Petter's Nautilus Grate Works in Hendford at bottom left. Production later moved to the Nautilus Stove Factory in dilapidated buildings in Vicarage Street but ultimately transferred to the foundry in Clarence Street.

The Yeovil Iron & Brass Foundry on the corner or Huish and Clarence Street (now under Tesco's car park) that had belonged to Sansbury & Savery.

gallery

James Bazeley Petter with his family. (Back Row) Tilly, John, Percy, Harry, Guy, Claude. (Middle Row) Hugh - added later, Gertrude, James, Charlotte, Mary. (Front Row) Dick, Eva and Ernest.

The Petter's chief residence, 'The Grange', in The Park. The house was demolished in 1976 as part of the Queensway dual carriageway project.